What is Industrial Automation?

Industrial automation is a set of technologies that uses control systems and equipment, such as computer software and robots, to perform tasks that were historically done manually, in other word, to enable automatic operation of industrial processes and machinery without the need for human operators. These systems operate industrial equipment automatically, significantly reducing the level of operator involvement which helps eliminate the possibility of human error, reduces costs, saves time, and achieves higher performance.

Main components of Industrial Automation

A vast range of tools are necessary for industrial automation. They include various control systems that incorporate different devices such as PLCs (programmable Logic Controllers), HMI (Human Machine Interface), Robotics, Vision Systems, SCADA (Supervisory Control and Data Acquisition), and more, these components impact the aspect of the manufacturing processes. Here are some mode details about these devices:

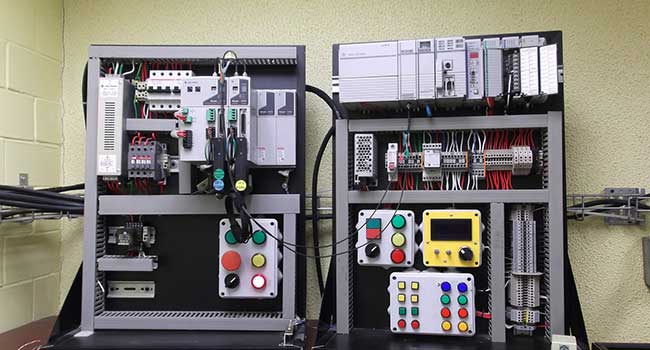

PLC (Programmable Logic Controller)

(PLC) is a digital industrial computer control system that is preprogrammed to execute automatic operations in industrial processes. It continuously makes decisions based on the state of input devices, a custom program needs to be designed and developed to control the state of output devices depending on the state of input devices.

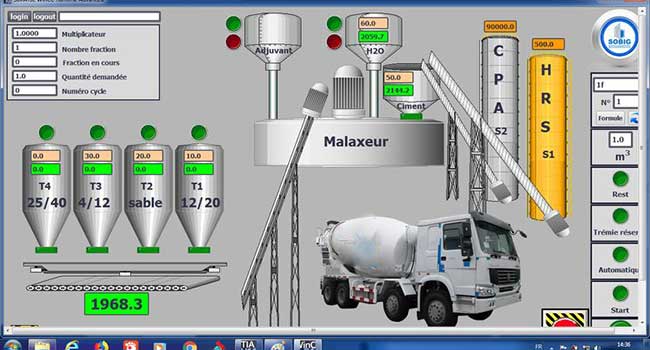

HMI (Human Machine Interface)

An HMI is a software application that enables interaction and communication between a human operator and the machine, or production system. It translates complex data into accessible information, enabling better control of the production process and its various applications.

SCADA (Supervisory Control and Data Acquisition )

SCADA systems control and monitor industrial processes. The system acquires and processes real-time data through direct interaction with devices, such as sensors and PLCs, and records events into a log file. SCADA is important for data analysis, and enables effective decision-making for optimization in industrial processes.

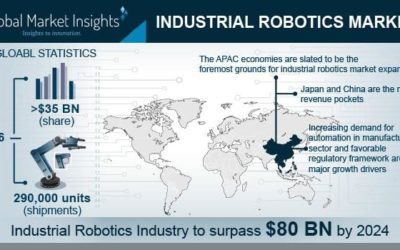

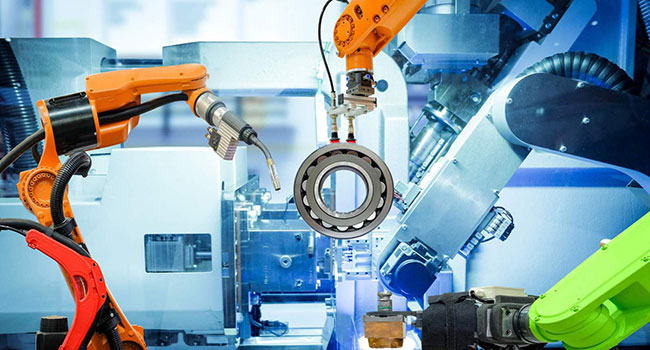

Robotics

An industrial robot is an automatically controlled, reprogrammable, multipurpose manipulator programmable in three or more axes. Robots can efficiently perform tasks in complicated or dangerous situations, improve production flow and quality, and increase safety for employees. Additionally, robots can make daily life much more comfortable or convenient.

Industrial Vision Systems

Industrial vision systems is the use of one or more cameras to inspect, check and analyze objects automatically, mainly in an industrial or production environment. The data acquired then can be sent to a PLC, and used to control a process or manufacturing activity.

Some credits: Unitronic